E-mail:info@jztggroup.com Tel:+86 18890395856

E-mail:info@jztggroup.com Tel:+86 18890395856

Type: Single-bottom/Double-bottom double cut (Single-cut for optional)

Raw Materials: Q355B High International Standard

Kelly Box:Kelly box 130mm, 150mm, 200mm (optional), Patented Design

Model:DN600-DN2500

Applicable Formation: Sand and gravel layer, pebble bed, flagstone, high strength of frozen soil, weathering rock and other complex hard strata.

![]() Request information on the tools

Request information on the tools

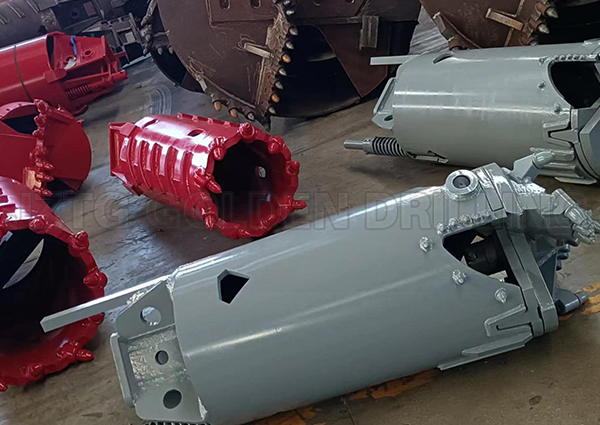

Introduction:

Rotary rig drilling buckets are usually used with kelly bars together for bored piles drilling construction. The applicable formation include: water-bearing sandy soil, sludge, clay, muddy sub clay, sandy gravel, cobble, and weathered soft formation, etc. The drilling bucket can be designed into cylindrical type and conical type according to bucket diameter, type of drilling rig and soil conditions. The opening and closing device can be operated manually, mechanically or mixed manner. The welding angle of bucket teeth can be designed according to formation conditions.

The bottom plate is made of high-strength Mn plate, and the cutting edge includes single-layer type and double-layer type; The soil inlet also includes single-bottom type and double-bottom type.

|

|

|

|

|

|

1-Used with rotary drilling rigs together for foundation bore pile drilling.

2-Suitable for very dense sand and gravel stratum, weak rock or stratum up to coarse grave.

3-Double cut rock bucket is also recommended for uncased bores, bigger diameter piles and secant pile walls.

Other kind of drilling bucket can be manufactured as to clients requirement.

Parameters of JZTG Rock Drilling Bucket:

Type

Model

Total Length

(mm)

Shell Length

(mm)

Shell Thickness

(mm)

Fixed bottom thickness (mm)

Rotating Bottom Thickness (mm)

Teeth Qty

Weight/kg

Double Cut Bullet Teeth Drilling Bucket

DN600

2100

1200

16

40

50

6

650

DN700

2100

1200

16

40

50

7

730

DN800

2060

1200

20

40

50

8

980

DN900

2060

1200

20

40

50

9

1080

DN1000

2180

1200

20

40

50

14

1260

DN1100

2180

1200

20

40

50

15

1390

DN1200

2180

1200

20

40

50

18

1600

DN1300

2180

1200

20

40

50

19

1740

DN1400

2180

1200

20

40

50

21

1970

DN1500

2180

1200

20

40

50

22

2150

DN1600

2180

1200

20

40

50

23

2420

DN1800

1980

1000

20

40

50

27

2870

DN2000

1980

1000

25

40

50

29

3570

DN2200

1780

800

25

40

50

31

4220

DN2500

1780

800

25

40

50

35

5040

JZTG Drilling Bucket Packing & Delivery:

JZTG Workshop Show:

New Factory Show:

Advantages:

1-The raw materials are from top leading raw steel factory, this guarantee the high structural strength of ou drilling bucket.

2-Simple operation, much easier for the operator to do the bored hole drilling job.

3-Hard facing strips for wear protection, high wear resistance.

4-Good roundness of the cylinder, optimize angle of drilling bits, throughout ventilation hole, make JZTG drilling buckets have higher drilling efficiency.

5-High quality carbide bullet teeth, teeth holder and pilot bit RP-4, to ensure that the cutting strength of drilling tools can reach the design requirements.

6-Double support plate unlocking design, enhanced protection block design and so on patent designs.

7-Modern workshop, advanced production equipment, automated robot welding, guarantee higher quality of JZTG drilling tools.

8-Factory direct supply, guarantee factory price and factory timely production and delivery.

Moden of drilling teeth for choose:

Bullet Teeth Drill Bits Optional: B47K20H, B47K19H, B47K17H, 3050, 3060, 3065, C30, C31HD, B85, B43H, etc.

The original JZTG plant(Golden Drilling) was founded in 1993, new brand JZTG established 2012. We are the real and the big drilling bucket manufacturer in China.

Choose JZTG, you are choosing to purchase from factory directly.

You will get: Factory Pirce, Professional OEM, Quality Production and Timely Delivery directlyl.

| Type | Model |

Total& Length (mm) |

Shell& Length (mm) |

Shell& Thickness (mm) |

Fixed& bottom& thickness& (mm) | Rotating& Bottom& Thickness& (mm) | Teeth& Qty | Weight/kg |

| Double& Cut& Bullet& Teeth& Drilling& Bucket | DN600 | 2100 | 1200 | 16 | 40 | 50 | 6 | 650 |

| DN700 | 2100 | 1200 | 16 | 40 | 50 | 7 | 730 | |

| DN800 | 2060 | 1200 | 20 | 40 | 50 | 8 | 980 | |

| DN900 | 2060 | 1200 | 20 | 40 | 50 | 9 | 1080 | |

| DN1000 | 2180 | 1200 | 20 | 40 | 50 | 14 | 1260 | |

| DN1100 | 2180 | 1200 | 20 | 40 | 50 | 15 | 1390 | |

| DN1200 | 2180 | 1200 | 20 | 40 | 50 | 18 | 1600 | |

| DN1300 | 2180 | 1200 | 20 | 40 | 50 | 19 | 1740 | |

| DN1400 | 2180 | 1200 | 20 | 40 | 50 | 21 | 1970 | |

| DN1500 | 2180 | 1200 | 20 | 40 | 50 | 22 | 2150 | |

| DN1600 | 2180 | 1200 | 20 | 40 | 50 | 23 | 2420 | |

| DN1800 | 1980 | 1000 | 20 | 40 | 50 | 27 | 2870 | |

| DN2000 | 1980 | 1000 | 25 | 40 | 50 | 29 | 3570 | |

| DN2200 | 1780 | 800 | 25 | 40 | 50 | 31 | 4220 | |

| DN2500 | 1780 | 800 | 25 | 40 | 50 | 35 | 5040 |